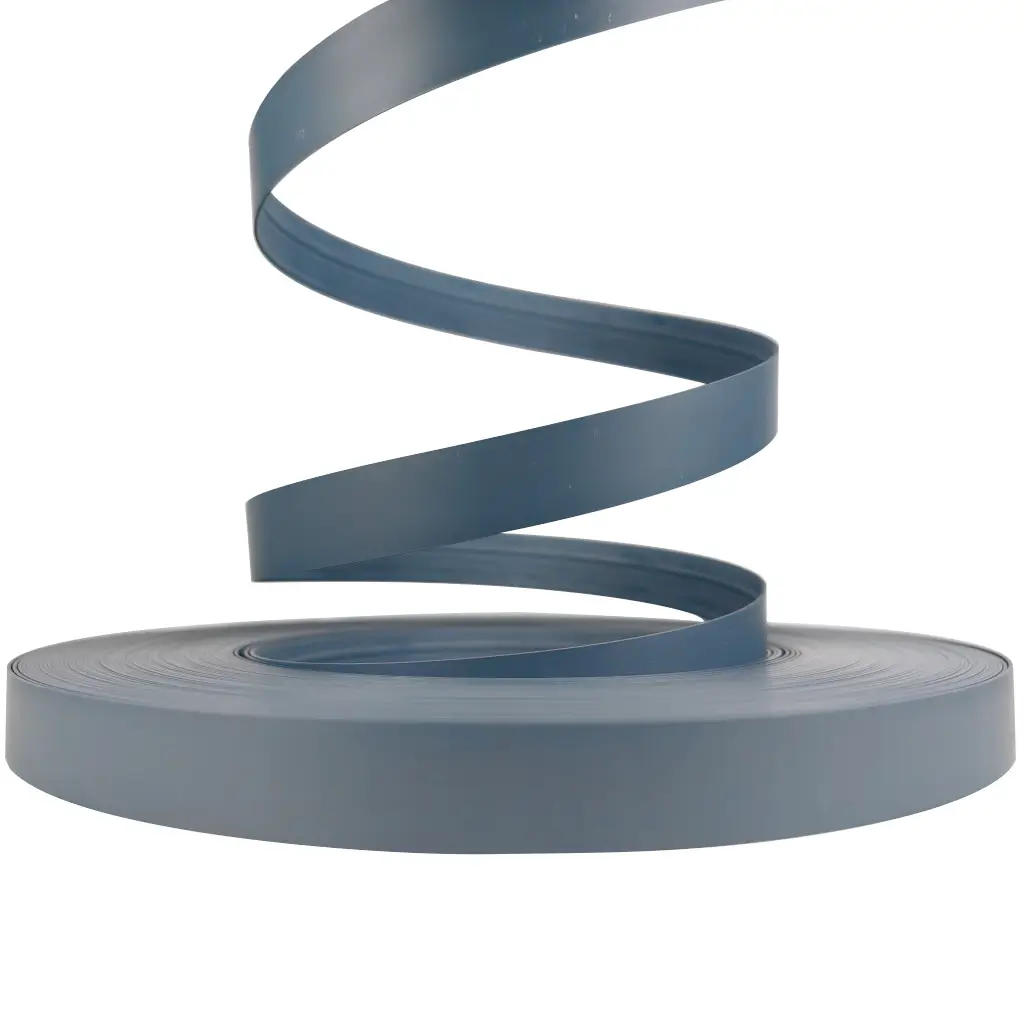

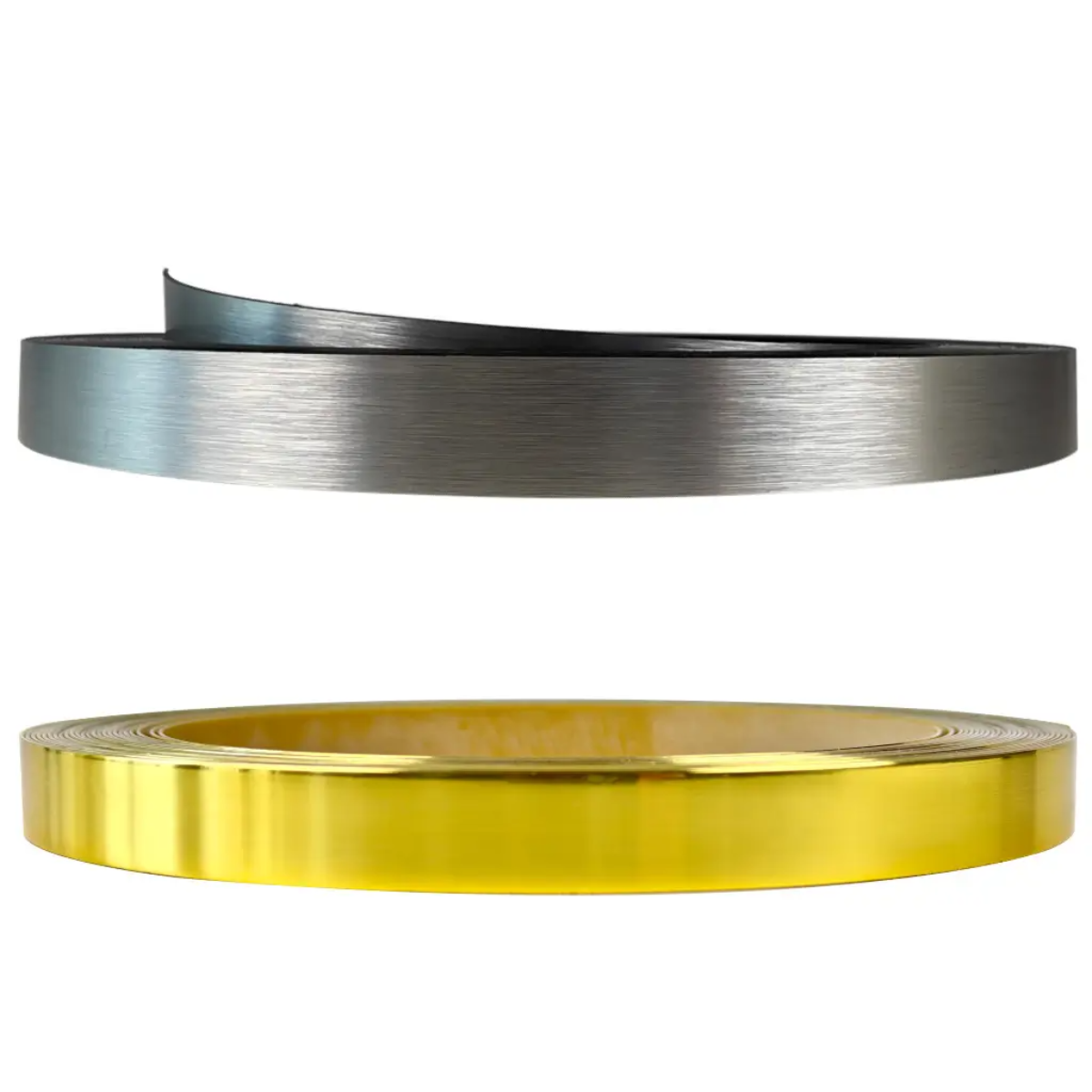

Wood grain furniture pvc edge banding tape customized for furniture suppliers

MOQ 3000 Meters

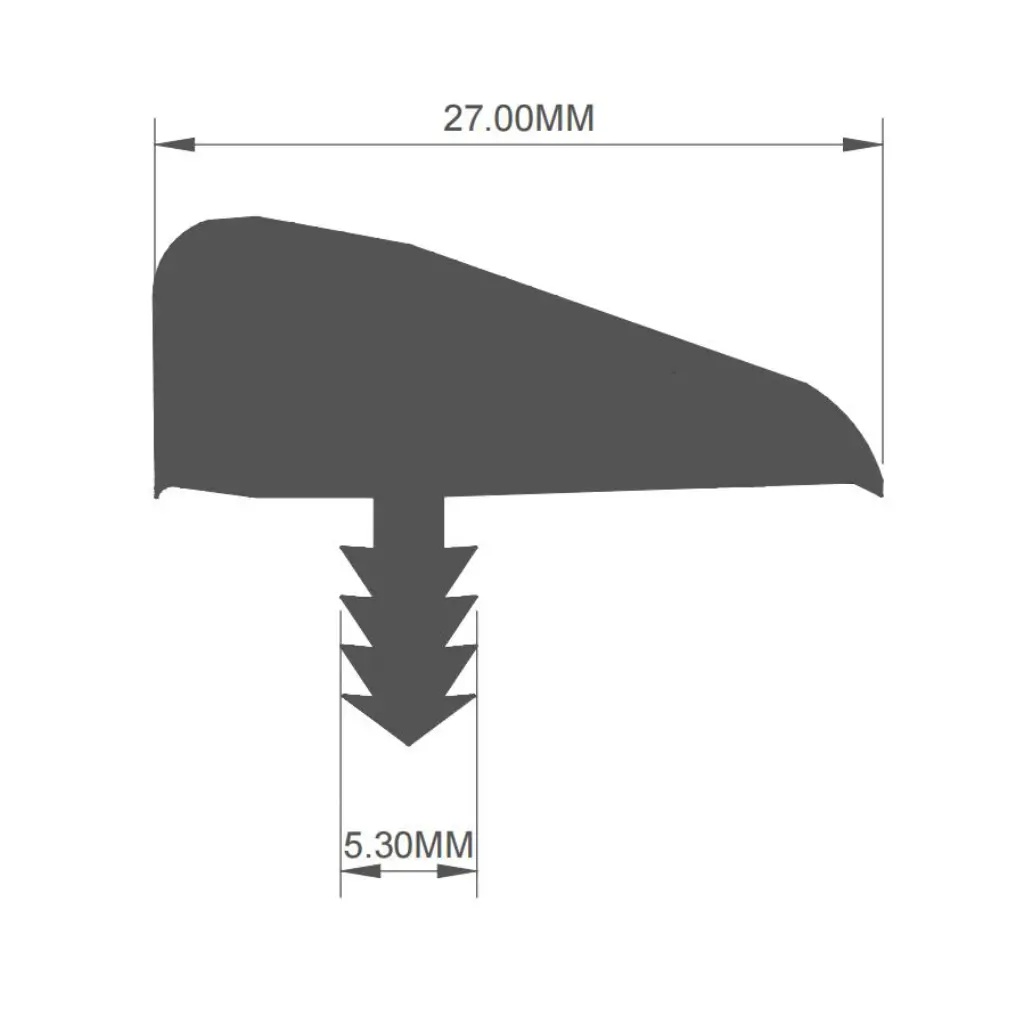

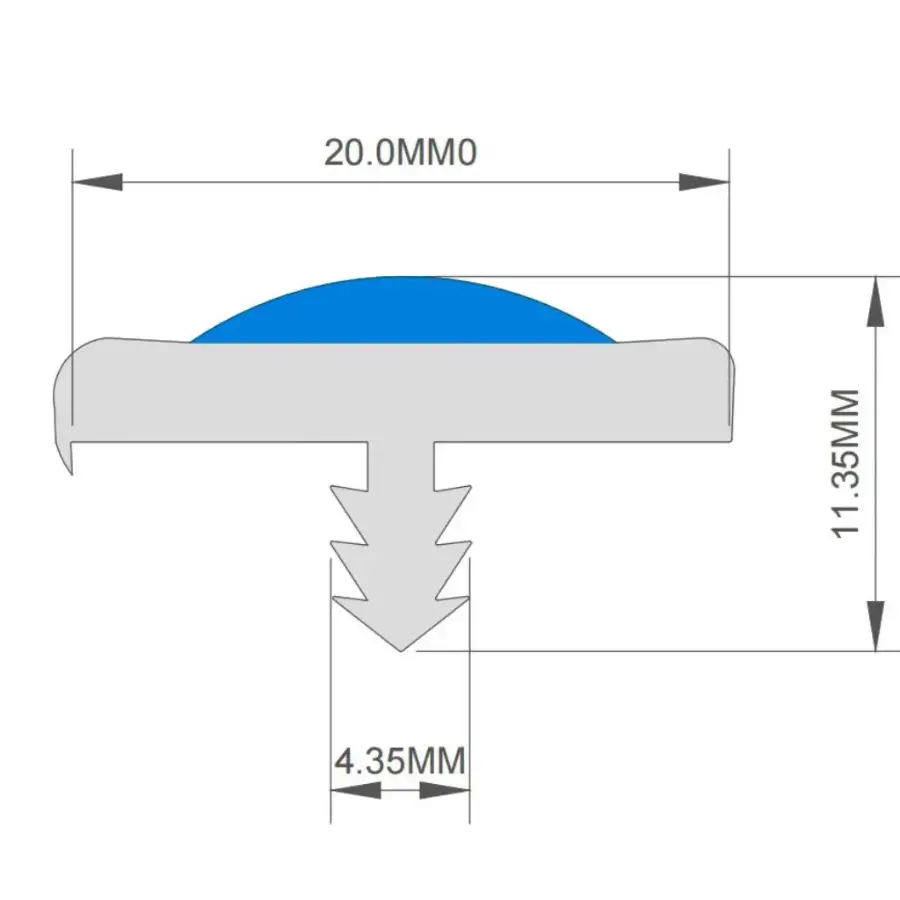

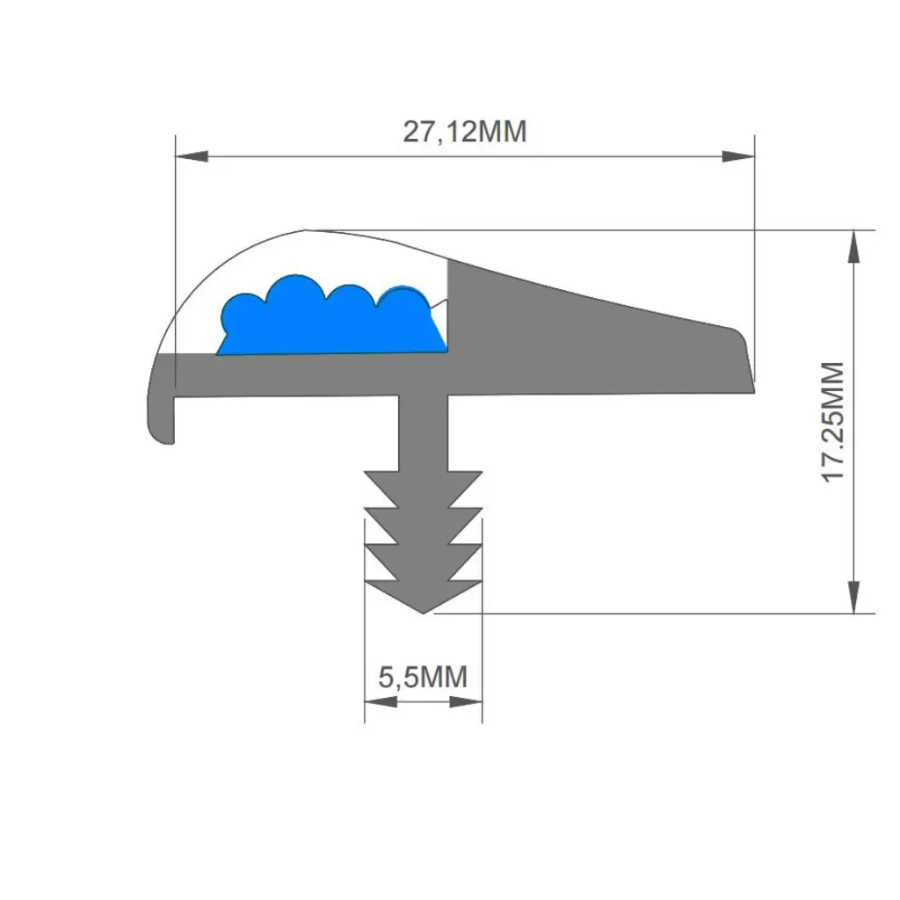

1. Thick is from 0.4mm to 2mm, width is from 10mm to 80mm.

2. Applied for Kitchen decorative edge banding, Office furniture edge banding, Board type furniture edge banding, also applies to mdf board,plywood,WPC board, kitchen cabinet, and other construction decorations.

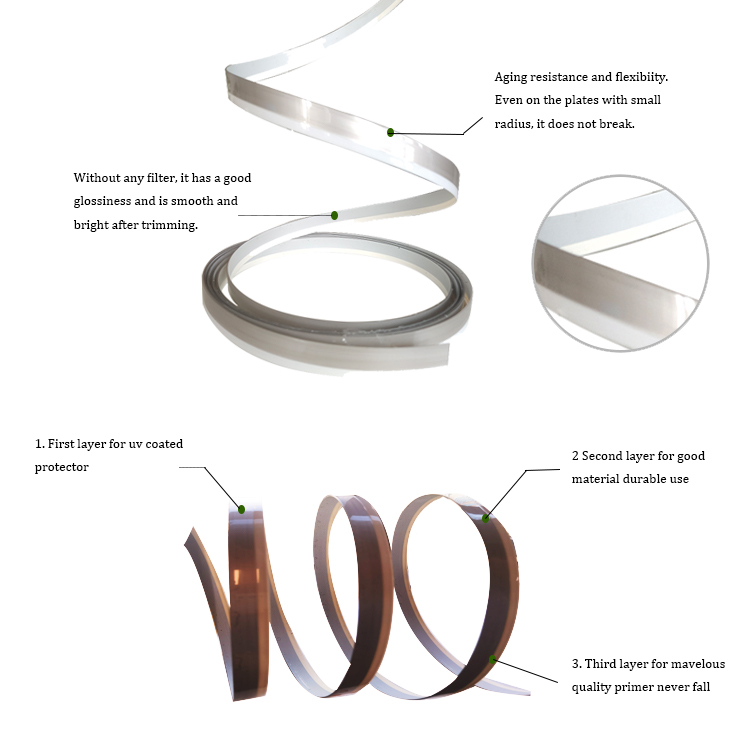

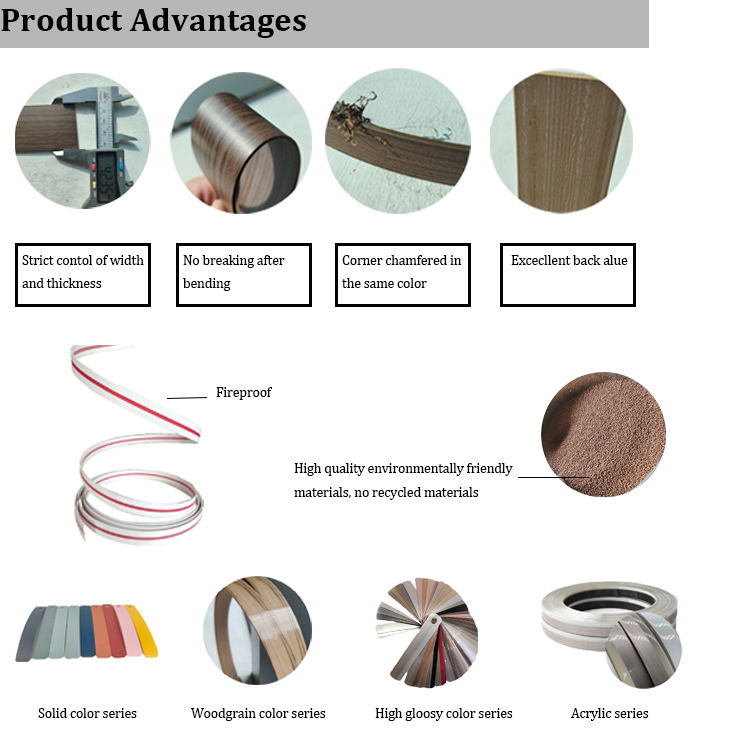

3. Features with outstanding characteristics, such as non-white after trimming and polishing, strong bonding strength, excellent light stability, superior durability, chemical resistance, non brittle, high strength, etc.

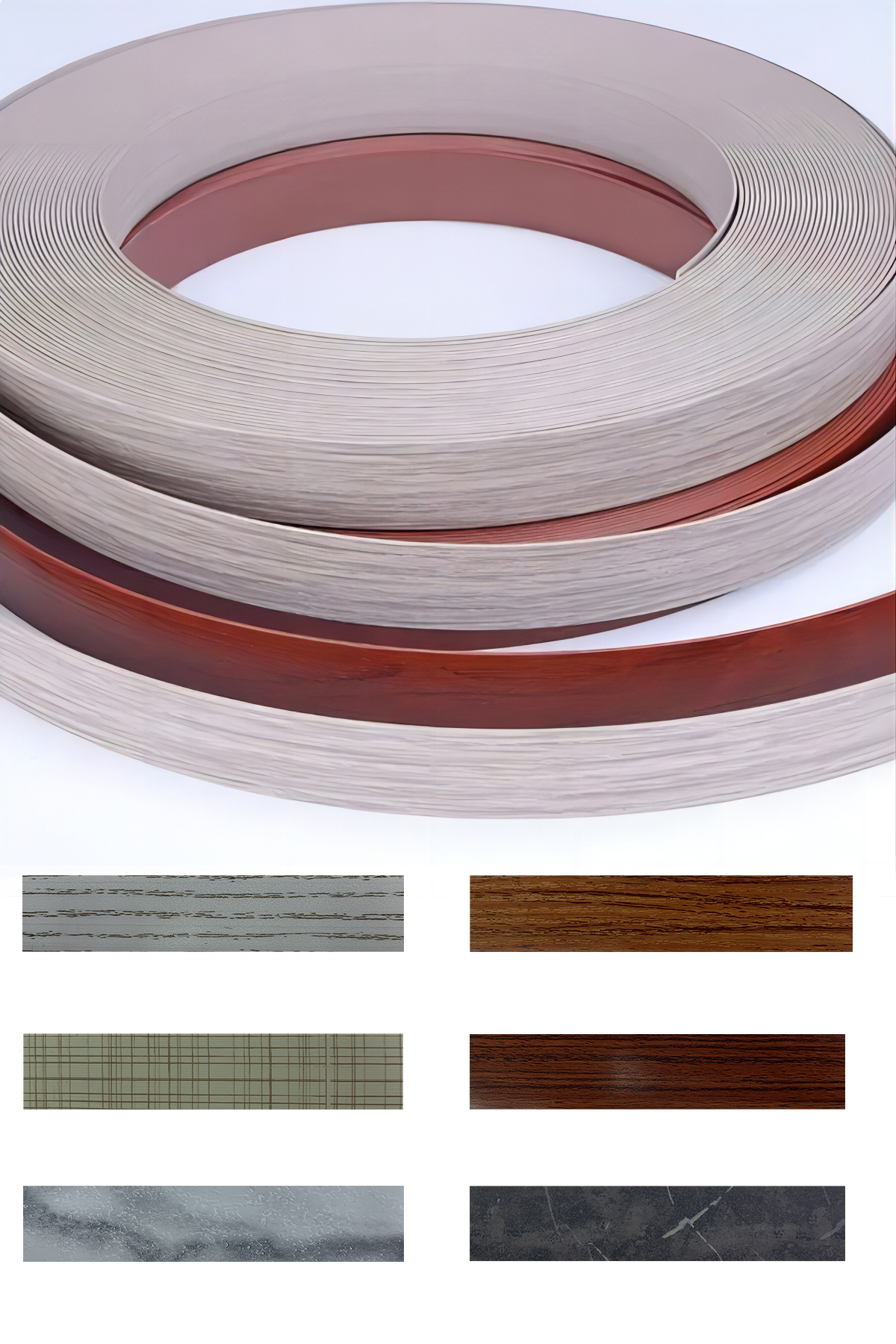

4. Colors: solid color, plain color,solid gloss, plain gloss.

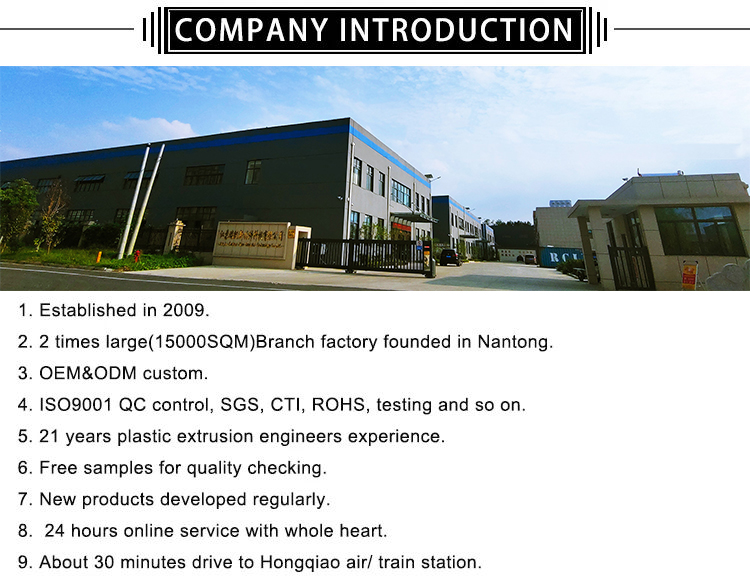

5. We have gained ISO9001 QC control

6. OEM and ODM service.

7. Free samples can be offered.

GET A FREE QUOTE

Product Description

Ruzihan are direct factory could customize the edge banding for clients. In our factory, the process of PVC edge banding production typically involves the following steps:

Mixing: The raw materials, including PVC resin, plasticizers, stabilizers, pigments, and other additives, are mixed together in a high-speed mixer to form a homogenous mixture.

Extrusion: The mixture is then fed into an extruder, where it is heated and melted into a molten mass. The molten mass is forced through a die, which shapes the PVC into the desired shape and size of the edge banding.

Cooling: The extruded PVC edge banding is then cooled by passing through a cooling tunnel, which reduces the temperature and solidifies the PVC into its final shape.

Cutting: The cooled PVC edge banding is cut into the desired lengths, usually using a high-speed saw.

Embossing: The PVC edge banding can be embossed with a pattern or texture using an embossing roller or press to give it a decorative appearance.

Packing: The finished PVC edge banding is packed into rolls or bundles, ready for shipment to customers.

Belowing is the information about our edge banding size and color,please kindly check it:

Q: 2.What about the lead time?

A: If you can send us your samples,we can copy and produce for you to test quality and color matching.Sample will be

ready within 7 days.

Q: 3.Do you have any MOQ limit for edge banding order?

A: Low MOQ,every size 3000m per color is available.

Q:4.How do you ship the goods and How long does it take to arrive?

A: We usually ship by sea.Airline is also optional.

Q: 5.Is it OK to print my logo on carton?

A: Yes,Please inform us formally before our production and confirm the design.

Q: 6.Do you charge for samples and freight?

A: In our company policy,the samples will be free for 1 solid color and 1 woodgrain.But freight will be on

customer’s account,freight charges will ben returned to you in your first official order.

Product Specfications

Related Products

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message